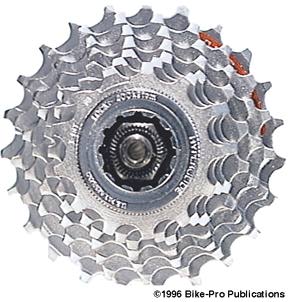

The cogs used in all the Shimano cassettes are made through a cold-forging process, where rolls of sheet metal are fed into a machine that stamps the metal several times as it moves through the machine. Each of the stamping dies, refines the shape, as it passes further through the machine, ultimately arriving at the end of this forging machine is a finished cog, that has the proper recesses for Hyperglide compatibility on the front of the cog, and the twisted teeth to grab the chain.

The second position cog, in some instances as a final step, has three holes threaded, for the cassette binder bolts, which hold the inner cogs together as a unit. These binder bolts are for the convenience of sliding the cogs on as a single unit only, they aren't absolutely necessary. The first position cog merely slides onto the hub.

Outside of the first position cog is "lock ring", which threads into the end of a HyperGlide cassette hub, holding the cogs securely onto the hub. To tighten or loosen this lock ring into the hub will require a Shimano TL-HG15 lock ring tool. You may also use the more readily available Park FR-5 Freewheel Tool or the Pamir Engineering Hyper-Cracker, (both made in the USA). The finished cogs are 1.9mm thick and use 3.0mm spacing between each them. The interior notches on the HyperGlide cassettes fit all of the HG hubs.

The XTR, Dura-Ace, 105SC, and Ultegra hubs are able to fit 8 cogs because the freehub body the cogs slide onto, is 35mm long rather than the 31mm of Shimano 7 speed hubsets. The added freehub body length was achieved by spacing the hubs flanges to under 55mm apart. Consult the hub section of this book to learn specifics about your hub and cassette compatibility.

The HG50 is the least expensive Hyperglide compatible cassette Shimano makes. It is a seven speed cog set. The lockring is made of steel with a black finish, and the first through the sixth position cogs are made of steel with a brown finish. The seventh position cog is plated in a Silver color that is likely Nickel or Zinc.

On the HG50 the second through seventh position cogs are held together with three long rivets, in place of the cassette binder bolts that are on their more expensive cassettes, so single cog replacements are impossible with out grinding away the rivets. The first position cog slides on separately, and the lock ring cinches the system to the hub.

The HG50 cassette is the stock cassette sold with all of Shimano's less expensive parts groups. It is compatible with, and can be used on 7 speed XT, DX, and LX mountain hubs also the older 7 speed Dura-Ace, Ultegra, 105SC, and RX100 hubs. It is compatible with XTR or Dura-Ace, Ultegra, or 105SC 8 speed hubsets for use as a 7 speed system only.

Understand that the HG50 is functionally the equivalent of the HG70, and HG90, it's just not fully plated like the 70 & 90, (to prevent rust), and the unit is riveted together. The HG50 is manufactured in 9 different cassette sprocket combinations, however we only sell six of them.

The HG70 7/8 speed cassette is the next step in the Shimano line and comes stock with the Deore LX, and came with the discontinued DX parts group. In road racing it is supplied with the RX100 and the 105SC parts groups.

They will, however, work on all Shimano 7 or 8 speed HyperGlide hubs, including Dura-Ace, and XTR (if you elect to use them), STX, Deore XT, Ultegra, 105SC and the less expensive parts groups. The HG70 uses cold forged cogs. All of the cogs, and the lock ring are plated in a dull Silver colored finish to prevent them from rusting, (probably Zinc, or Nickel, it's difficult to tell).

The second position cog has three threaded holes for the cassette binder bolts to thread into from the rear of the cassette unit. The cogs are 1.9mm thick and are spaced apart with 3mm plastic spacers. The binder bolts are un-plated Black steel with a 4mm six sided head.

The HG70 7 speed is manufactured in 9 different cassette sprocket combinations, and we sell all of them. The HG70 8 speed cassettes are for use with Dura-Ace, Ultegra or 105SC 8 speed hubsets. It's is manufactured in 5 different road racing, cassette sprocket combinations, and we sell them all.

This is a 7 speed HG cassette that has an 11 tooth first position cog. It is only the 11 tooth cog that makes it different from the HG70 written about above. The 11 tooth inner is needed for the Hyper Drive-C compact cranksets to have a full gear ratio range.

The HG70-C comes only in a 11-13-15-18-21-24-28 geared cluster. It is sold with the 7 speed LX Hyper-C parts groups. Remember in 1995 the LX group will become 8 speed. The HG70-C cluster weighs 302.5 grams.

The HG90 cassette comes stock with the pre-1994 Deore XT parts group, also in road racing with Ultegra 7/8 parts group. They will, however, work on all Shimano 7 or 8 speed HyperGlide hubs, including Dura-Ace, and XTR (if you elect to use them), Deore LX, DX, STX, 105SC, RX100 and the less expensive parts groups. The HG90 8 speed cassette is for use with Ultegra and 105SC 8 speed hubsets, where Shimano has spaced the hub flanges slightly closer together to accommodate a longer freehub body.

Because the spacing and thickness of the cogs is the same as all HG cogs, you will not be able to use a HG90-8 on a seven speed MTB or road hub. All of the cogs and the lock ring are bright Chrome plated to prevent them from rusting. The second position cog has three threaded holes for the cassette binder bolts to thread into from the rear of the cassette unit. The cogs are 1.9mm thick and are spaced apart with 3.0mm plastic spacers.

The binder bolts are un-plated Black steel with a 4mm six sided head, Shimano makes a tool for their removal called the TL-FC20, but it is only available by buying a Dura-Ace crankset. A 4mm box wrench or a small adjustable wrench can be used in place of the TL-FC20 tool. Because the cassette unit is not riveted together, singular sprockets may be replaced should they show excessive wear or if a tooth becomes chipped through hard use. Again the HG90 primary difference is it's thick bright chrome plated finish.

The HG90 7 speed cassette is manufactured in 9 different cassette sprocket combinations, and we sell all of them. The HG90 8 speed cassette for the Dura-Ace, Ultegra or 105SC hubset is manufactured in 5 different road racing, cassette sprocket combinations, and we sell them all. The 8 speed road geared set will also work on the 1994 XT and XTR hubs for compact gearing applications.

In the 1992 model year, Shimano introduced the eXTRa expensive group of components for mountain bikes, elevating MTB part quality to the level of the Dura-Ace parts used in road racing. The XTR cassette has eight cogs, with some specific changes to reduce the weight of the sprocket assembly. The cogs are cold forged, HyperGlide compatible, and have dull Nickel plating giving them a Platinum/Satin appearance.

The stamping process cuts away much of the steel at the center of the cog, and has tiny holes in the perimeter, to reduce the weight of these steel sprockets. On the HG series cassette cogs, the sprocket slides directly onto the hub's freehub body with steel to steel contact. The XTR cogs bolt onto an aluminum carrier that has four "spider arms" like those on a right crank arm.

There are 2 versions of this spider arm assembly, a "type-Q" for the 12-28 model which holds the four largest sprockets, and a "type-P" for the 12-32 model which holds the five largest sprockets. These spider arms have exact and fixed positions for the four or five largest cogs to bolt directly to it using four #1 Phillips head machine screws to fasten each of them to the spider.

The center of this forged aluminum carrier is notched to fit onto the freehub body, and merely slides on. The remaining four cogs and a necessary 3.0mm aluminum spacer, (all provided), slide onto the hub body, with a Chrome steel lock ring cinching the entire assembly to the hub. Previously, (in the HG series cassette), we have said that the HG50 & 90 series cassettes weren't compatible with the XTR hubs, this is true only because they don't have 8 cogs.

Shimano made the XTR hubs 8 speed compatible by paring down the shoulder that the cogs butt against on the seven speed model freehub, creating enough space to fit 8 of them within the 135mm over lock nut dimension. The XTR cogset with the spider arm can be used on a seven speed hub, if you use the "type-Q" model, and if you are prepared to not install either the second or third position cog.

The XTR set is considerably lighter than the standard HG series cassettes. The weight of the 13 tooth second position cog is 20 grams, and the weight of the 14 tooth third position cog and it's necessary spacer is 21 grams. Merely deduct this weight from it's total weight to derive it's seven speed weight and compare to the HG90 cassette. With the 13 tooth second removed it's just 245 grams instead of the 314 grams of the HG90 12-28 seven speed, it's functional equivalent.

The spacing and width of the XTR cogs is the same as all HG cogs. Trying this with the "type-P" model would leave an untenable gap in your shifting ratios, and it's not recommended. The XTR cassette is made in two combinations, and we sell them both.

A variation on the M900 cassette is the M737-8. Introduced in the 1994 model year, it comes with the '94 XT parts group as Shimano introduces the Hyper-C XT crankset. The M737 uses an aluminum carrier for the cogs like the M900. In this case the largest four cogs are riveted to the carrier. The cogs are chrome plated steel with the Hyper Glide teeth. Like the HG70-C, the real important difference is the 11 tooth first position cog needed for the compact cranks instead of the 12 tooth used on the others.

This will become the 8 speed cogset needed when the LX parts group becomes 8 speed in 1995. The M737 is made only with 11-12-14-16-18-21-24-28 gearing and weighs 255.5 grams

The CS-7401 8 speed cassette system is the stock HyperGlide SIS cogset used with the DA 7403 rear cassette hub, (first introduced in the 1991 season), and the DA 7463 disk wheel rear cassette hub introduced in the 1992 season. The eight cogs are 1.9mm thick, made of cold forged steel, with the distinctive HyperGlide teeth, in a dull Platinum-silver color.

The CS-7401 set uses 3.0mm thick aluminum spacers rather than the Grey plastic ones used in their other cassettes. Since the CS-7401 series is for small block use only, the torsion against the freehub for the largest cog isn't as great as the HG series cassettes, therefore, there are no cassette binder bolts needed for the CS-7401 series. The lockring has a thin spring against the first position cog, to hold it in place, should it somehow loosen up in use.

This cogset can be used on any 8 speed HyperGlide hubset requiring a small block, including DA, Ultegra and 105SC. The CS-7401 8 speed cassette is manufactured in 5 different cassette sprocket combinations, and we sell all of them.